RMC is trending in the form of material for giving high-end durability to construction sites. The advantages of picking the RMC from Rodidust.com are innumerable. Rodidust is one of the best RMC Suppliers In Gurgaon, and with us, you can get plenty of advantages of taking the RMC as a part of the construction. It will make sure that the RMC will deliver aesthetics and strength.

With Rodidust, you can get the availability of the M20, M25, M30, up to M100 strength of the ready mix cement grades.

Product images are used for reference purpose only. Actual products may differ sightly in appearance

Product images are used for reference purpose only. Actual products may differ sightly in appearance

Product images are used for reference purpose only. Actual products may differ sightly in appearance

Product images are used for reference purpose only. Actual products may differ sightly in appearance

Product images are used for reference purpose only. Actual products may differ sightly in appearance

Product images are used for reference purpose only. Actual products may differ sightly in appearance

Product images are used for reference purpose only. Actual products may differ sightly in appearance

Product images are used for reference purpose only. Actual products may differ sightly in appearance

Ready Mixed Concrete (RMC) is a primary material used in buildings and heavy civil infrastructure projects. Projects ranging in size from a single house to high-rise buildings all need RMC for their construction. RMC consists of coarse aggregates, fine aggregates, cement, water, fly-ash and admixtures (specified).

It is a modern technique of production of concrete in massive quantities away from the actual site of placing. It is very useful where demand of concrete is very high and construction sites are in congested areas, where mixing on site is not possible due to lack of storage place. RMC is ready-to-use material widely adopted throughout the world. It provides higher strength and durability to the structure.

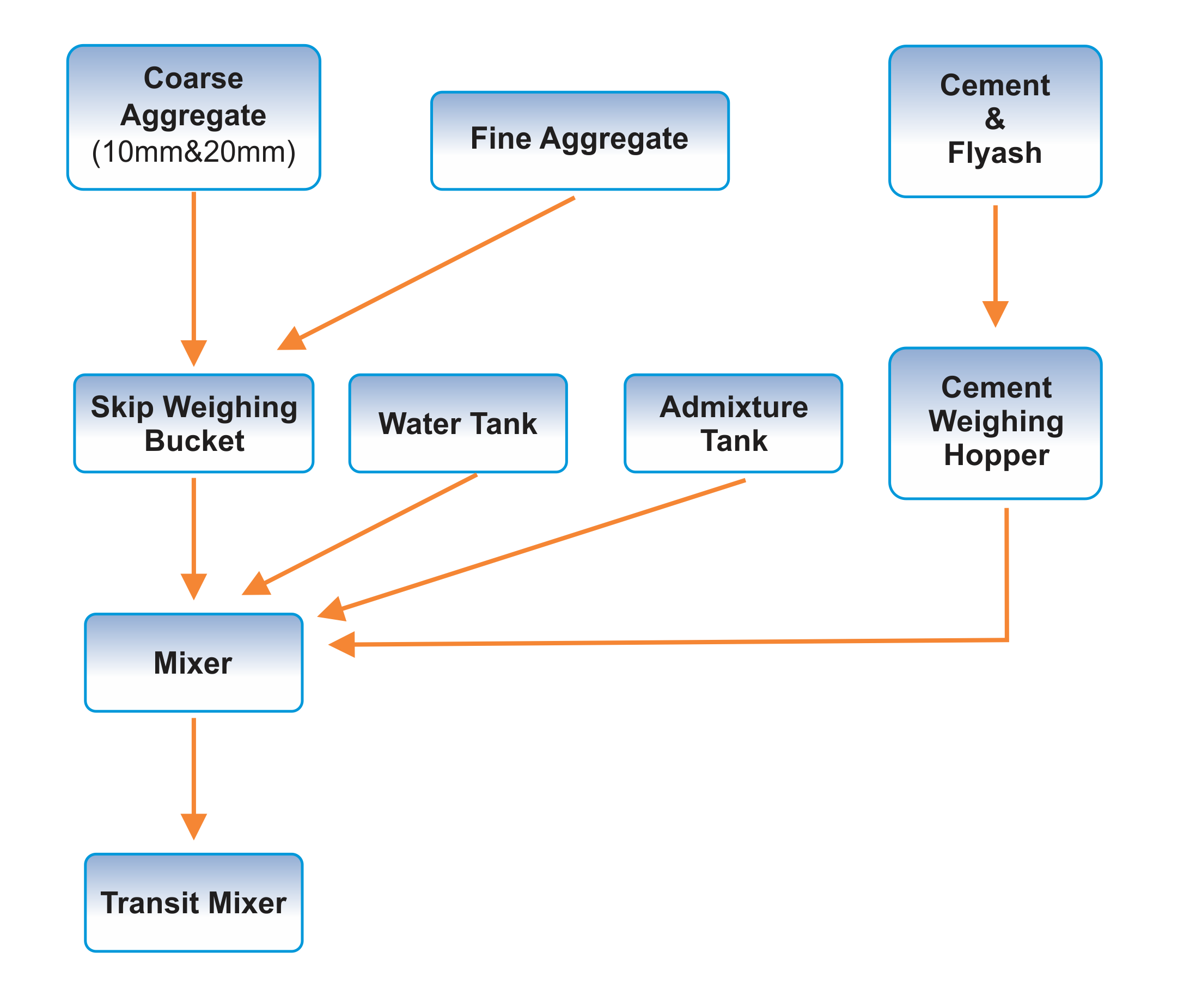

Ready Mix Concrete is made in batching plants. The main ingredients used to make RMC are Coarse Aggregates (Aggregates-20mm, Aggregates-10mm), Fine Aggregates (M-sand/Stone dust/ Crushed sand/ Coarse Sand), Cement, Fly ash, Admixture and Water. Coarse Aggregate and Fine Aggregates (M-sand/Stone dust/ Crushed sand/ Coarse Sand) work as filler material in ready mix concrete, while cement is binding material, water is used for hydration and admixture is added to increase the workability of concrete. Concrete batching plant process starts from the feeding of aggregates into individual bins. The aggregates are fed into bins according to their respective sizes. These aggregates will be weighed individually as per the design set in the control panel. After weighing, it will be transferred to the mixing unit. Above the mixing unit, the weighing hopper known as skip weighing bucket is placed to weigh ingredients and then transfer it to following mixing unit. Cement is transferred to the weigh hopper by means of screw conveyer whereas water is pumped into that hopper. As per the time set in the mixing unit, all the contents were mixed. Further, the mixer will discharge the prepared RMC into transit mixer.

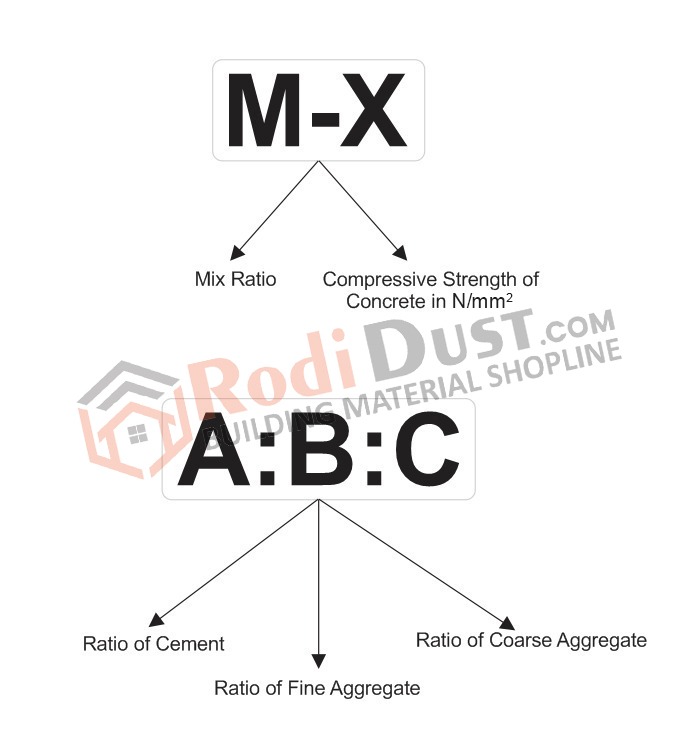

Grade is defined as the minimum strength of concrete after 28 days of construction with proper quality control. Concrete grades are denoted by M-7.5, M-10, M-15, M-20, M-25, M-30, M-35 and M-40 according to their compressive strength. M denotes Mix design of concrete followed by the compressive strength number in N/mm2. Mix is the respective ingredient proportions which are cement, fine aggregates and aggregate.

| GROUP | CONCRETE GRADE | MIX RATIO | COMPRESSIVE STRENGTH |

|---|---|---|---|

| ORDINARY CONCRETE | M-7.5 | 1:4:8 | 7.5 N/mm2 |

| M-10 | 1:3:6 | 10 N/mm2 | |

| M-15 | 1:2:4 | 15 N/mm2 | |

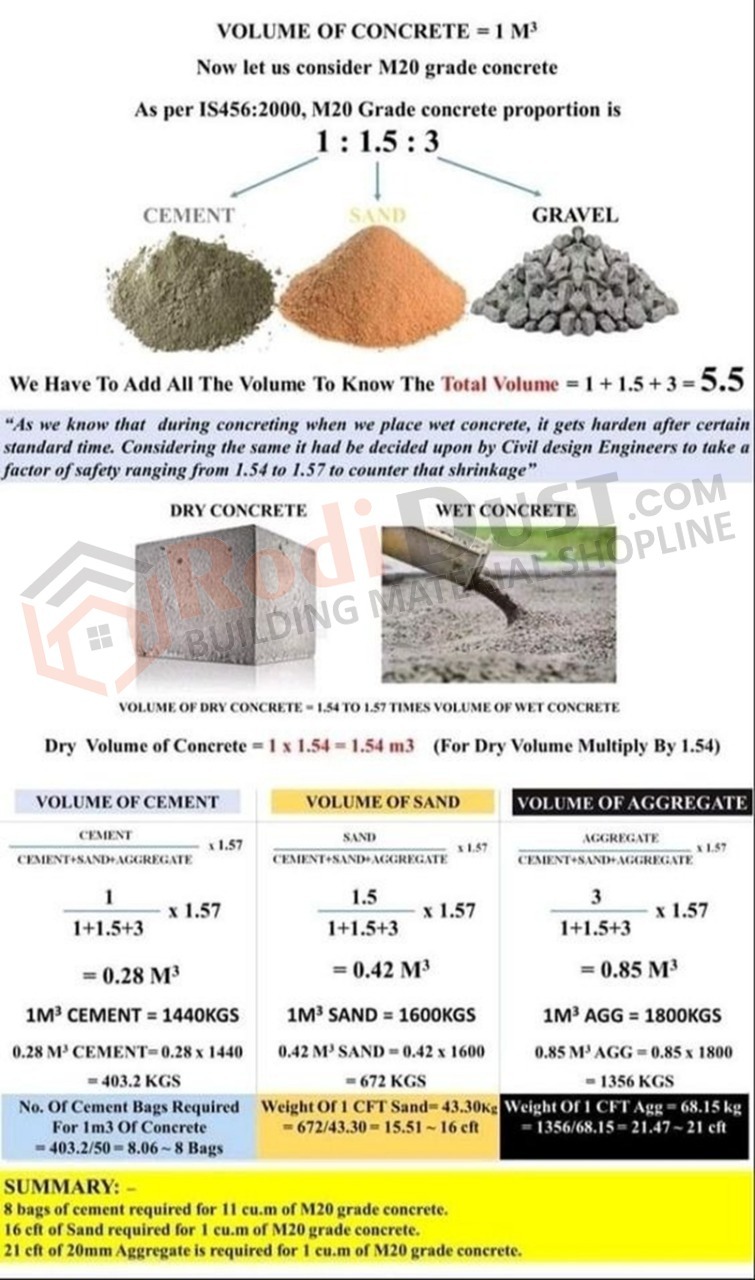

| M-20 | 1:1.5:3 | 20 N/mm2 | |

| STANDARD CONCRETE | M-25 | 1:1:2 | 25 N/mm2 |

| M-30 | Design Mix | 30 N/mm2 | |

| M-35 | Design Mix | 35 N/mm2 | |

| M-40 | Design Mix | 40 N/mm2 |

As per IS 456:2000 the grades less than M-20 should not be used in RCC works. The minimum grade of concrete for Plain Cement Concrete (PCC) is M-15 whereas for Reinforced Cement Concrete (RCC) is M-20 which is used for construction of roof slab. M-7.5 is used in PCC work as in the base under the foundations.

Hence the advantages of RMC are realized by engineers and contractors in construction industry. So, it is widely used.

The varied range of ready mix concrete can a lot of benefits to construction work. You can get the concrete that will be giving the excellent durability. We the best Building Materials Suppliers in Gurgaon, Delhi NCR make sure that you will get best quality of RMC in Gurgaon, Delhi NCR on time at affordable prices