READY MIX CONCRETE SUPPLIERS

Ready Mix Concrete Suppliers

First of all to know the Ready Mix Concrete Suppliers one should have basic knowledge of Ready Mix Concrete (RMC) also, to begin with this topic one should clearly knows about what is RMC? and what are its advantages and disadvantages too.

What is READY MIX CONCRETE (RMC) ?

Ready Mix Concrete (RMC) refers to the concrete which is pre manufactured at batching plant (RMC PLANT) instead of being manually or hand made prepared at the construction site.

What Material are used in RMC ?

It is a blend of Aggregates (Aggregate 10mm/20mm, Coarse Sand/Stone Dust/M sand), Cement (PPC, OPC), Water and Admixture to enhance the workability and durability of concrete.

Different grades of concrete :

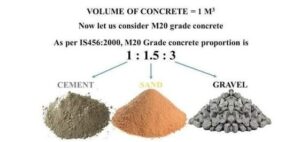

Different grades of concrete has different Concrete Mix proportions which means different concrete mix ratios. As Per IS456:2000, the Concrete mix design has the following concrete mix proportions :-

DESIGN MIX (WITH FLY ASH)

|

Grade |

Cement | Fly Ash | Agg-

Regate 20mm |

Agg-

Regate 10mm |

Sand | Water | Admixture | Total |

| (KG.) | (KG.) | (KG.) | (KG.) | (KG.) | (KG.) | (KG.) | (KG.) | |

| M-7.5 | 110 | 140 | 612 | 407 | 840 | 175 | 1 | 2285 |

| M-10 | 150 | 140 | 604 | 404 | 828 | 174 | 1.16 | 2301.16 |

| M-15 | 220 | 110 | 614 | 410 | 776 | 181 | 1.65 | 2312.65 |

| M-20 | 260 | 90 | 646 | 431 | 756 | 175 | 2.1 | 2360.1 |

| M-25 | 280 | 90 | 642 | 426 | 745 | 177 | 2.59 | 2362.59 |

| M-30 | 320 | 80 | 633 | 423 | 738 | 176 | 2.8 | 2372.8 |

| M-35 | 360 | 80 | 644 | 428 | 691 | 176 | 3.52 | 2382.52 |

| M-40 | 400 | 80 | 633 | 423 | 681 | 173 | 3.84 | 2393.84 |

DETAILS OF DESIGN MIX (WITHOUT FLY ASH)

|

Grade |

Cement | Aggregate 20mm | Aggregate

10mm |

Sand | Water | Admixture | Total |

| (KG.) | (KG.) | (KG.) | (KG.) | (KG.) | (KG.) | (KG.) | |

| M-7.5 | 200.0 | 638.0 | 426.0 | 876.0 | 176.0 | 1.00 | 2317.00 |

| M-10 | 240.0 | 628.0 | 418.0 | 858.0 | 177.0 | 1.20 | 2322.20 |

| M-15 | 280.0 | 642.0 | 428.0 | 812.0 | 173.0 | 1.40 | 2336.40 |

| M-20 | 320.0 | 641.0 | 428.0 | 812.0 | 170.0 | 1.92 | 2372.92 |

| M-25 | 350.0 | 652.0 | 434.0 | 761.0 | 175.0 | 2.45 | 2374.45 |

| M-30 | 380.0 | 646.0 | 431.0 | 753.0 | 171.0 | 2.66 | 2383.66 |

| M-35 | 420.0 | 652.0 | 436.0 | 699.0 | 176.0 | 3.36 | 2386.36 |

| M-40 | 460.0 | 641.0 | 426.0 | 689.0 | 175.0 | 3.68 | 2394.68 |

Comparison between Ready Mix Concrete and Site Mix Concrete

| Factor Being Considered | Ready-Mix Concrete | Site-Mixed Concrete |

| Time | Delivered ready to use and less time-consuming. | Slower process due to multiple steps, formulas and the setting time. |

| Equipment | Does not require equipment at the construction site. | Requires a weigh batch mixer to make concrete on-site. |

| Distribution | Can be delivered to multiple sites within a project. | Must be mixed at the exact point of use, to avoid contamination |

| Recommended Application | High-rise structures | Low-rise structures |

| Storage Requirements | Does not require additional storage space for raw materials | Requires a controlled storage space, to manage and protect materials like cement and aggregates |

| Waste | Material waste at the site is minimal | There is some material loss during storage and mixing |

| Quality | Consistent quality, thanks to an automated and controlled environment. | Continuous supervision is for consistency among batches. Setting time may vary due to inconsistency. |

| Work force | Skilled labour is required only to pour and compact the concrete. | Requires more man-hours to prepare concrete at the project site. |

| Material take-off | Concrete can be calculated as a single item. | Materials must be estimated individually, and their purchase must be planned separately. |

| Space | Requires a suitable access for the concrete mixer truck. | Requires space for material storage and batch mixers. |

| Batch Size | Large amounts of concrete can be delivered. | Mixing large amounts of concrete on-site is difficult. |

| Site location | If the batching plant is located very far from the construction site, the concrete will require retardants and other admixtures to prevent setting. Transportation costs will increase, there may be quality concerns. | Requires the transportation of all materials and mixing equipment to the construction site. |

Conclusion

Hence, Ready-mix concrete tends to be better for many projects, in spite of its higher cost. Ready-mix concrete offers a higher quality, and variation between batches is minimal when concrete is prepared in a plant environment. Another key factor is the project’s location: transportation requirements partially determine which type of concrete is more suitable for a project.

Ready-mix concrete is normally recommended for large projects that require a high volume. On the other hand, site mixing is a better option for small projects and renovations, where the concrete volume is smaller.

Purchasing

Rodi Dust Marketing & Distributions Pvt. Ltd. is one of the best READY MIX CONCRETE Suppliers In Gurgaon, Delhi NCR and with us, you can get plenty of advantages of taking the RMC concrete as a part of the construction. It will make sure that the RMC Concrete will deliver aesthetics and strength.

Rodidust, the reputed Ready Mix Concrete supplier, has the latest technology of RMC that works as per the industry quality standards. We fulfill your Ready Mix Concrete (RMC) need for all construction sites. The best quality material used in the process and with fast delivery makes Rodidust the best. With the quality RMC Rodidust.com supply, you can rest assured about getting the increased construction speed.

With Plant Presence at DELHI, GURGAON, FARIDABAD, GHAZIABAD, NOIDA, GREATER NOIDA.

Feel Free to Call Us on 9582872872, 8368450521

or visit us at www.rodidust.com